| Specification & Type | Unit | RMM620 |

|---|---|---|

| Working Width | mm | Min: 20 Max: 200 |

| Working Thickness | mm | Min: 8 Max: 120 |

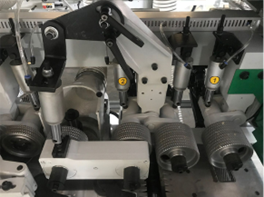

| Number of Spindles | 6 | |

| Speed of Spindle | r/min | 6000 |

| Cutting Circle (Max ~ Min) | mm | First Bottom Spindle: *110 ~ *145 Right Side Spindle: *110 ~ *180 Left Side Spindle: *110 ~ *180 Second Right Spindle: – First Top Spindle: *110 ~ *180 Second Top Spindle: *110 ~ *180 |

| Working Width | mm | Min: 20 Max: 200 |

| Working Thickness | mm | Min: 8 Max: 120 |

| Number of Spindles | 6 | |

| Spindle Speed | r/min | 6000 |

| Cutting Circle (Max ~ Min) | mm | First Bottom Spindle: *110 ~ *145 Right Side Spindle: *110 ~ *180 Left Side Spindle: *110 ~ *180 Second Right Spindle: – First Top Spindle: *110 ~ *180 Second Top Spindle: *110 ~ *180 Second Bottom Spindle: *110 ~ *180 |

| Spindle Diameter | mm | *40 |

| Basic Motor Power | First Bottom Spindle: 5.5kW / 7.5HP Right Side Spindle: 4kW / 5.5HP Left Side Spindle: 4kW / 5.5HP Second Right Spindle: – First Top Spindle: 5.5kW / 7.5HP Second Top Spindle: 5.5kW / 7.5HP Second Bottom Spindle: 5.5kW / 7.5HP Feed: 4kW / 5.5HP Feed Beam Rise & Fall: 1.1kW / 1.5HP |

|

| Total Motor Power | kW | 35.1kW / 48HP |

| Feed Speed | m/min | 6.30 (Inverter for Feed) |

| Dust Outlet Diameter | mm | *130 |

| Overall Machine Dimensions (L*W*H) | mm | 4150*1650*1700 |

| Weight | tons | 4 (approx.) |

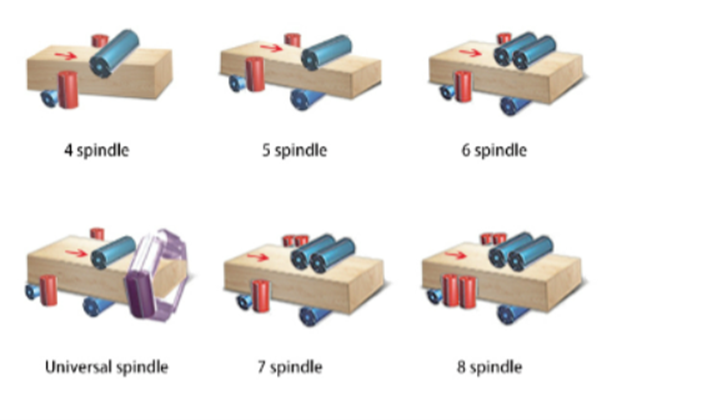

FOUR SIDE MOULDER / FIVE SIDE MOULDER/ SIX SIDE MOULDER

function of 4 sided planers and profiling machines, moulders allow the following woodworking (depending on the model): board, straightening on 4 sides, planning on 4 sides, eliminating the crooked/raw part of the wood, perfect board, removing wood imperfections, profiling, excavations, handrails, door frames, skirting boards, frames, window frames, match boarding, wood cutting, shutters and sills for windows, beams.

5 SIDE MOULDER / SIX SIDE/ UNIVERSAL EXPLAINED IN THE DIAGRAM: