Specifications:

| Model |

BK7.5-8g

|

| Power |

7.5KW

|

| Gas Production Volume |

1.2m*/min

|

| Exhaust Pressure |

0.8Mpa

|

| Net Weight |

200KG

|

| Length,Width & Height: |

800*620*800

|

| Model |

BK7.5-8g

|

| Power |

7.5KW

|

| Gas Production Volume |

1.2m*/min

|

| Exhaust Pressure |

0.8Mpa

|

| Net Weight |

200KG

|

| Length,Width & Height: |

800*620*800

|

| Item | Details |

|---|---|

| Model | BK7.5-8g |

| Power | 7.5 Kw |

| Gas Production Volume | 1.2 m³/min |

| Exhaust Pressure | 0.8 Mpa |

| Net Weight | 200 kg |

| Dimensions (L x W x H) | 800 x 620 x 800 mm |

Compressed air systems will always produce moisture. If the pressure dew point is reached, the water vapor will condense into water and can impact your productivity and equipment. An air dryer eliminates the moisture your compressor produces so that you can have pure, clean compressed air for your facility.

Permanent Magnet motor adopt dual housing design with IP65 protection grade, there have space left for oil channel between the inner housing and outer housing. It takes use of compressor itself lubricant system to cool down motor circularly through its oil channel, no touch with outside cooling air, and more suitable for the dusty environment, it breaks through the traditional air-cooling motor disadvantage with IP23 or IP54 protection grade.

PM motor rotor is directly mounted on the aired shaft, no gears or belts, no coupling, zero transmission loss, Easy for installation, No need to make adjustment, Better protection for inner parts of PM motor. There’s no bearing for the PM motor, so motor is 100% free maintenance, Reduce maintenance cost.

SCREW COMPRESSORS

own-to-earth investment for the future.

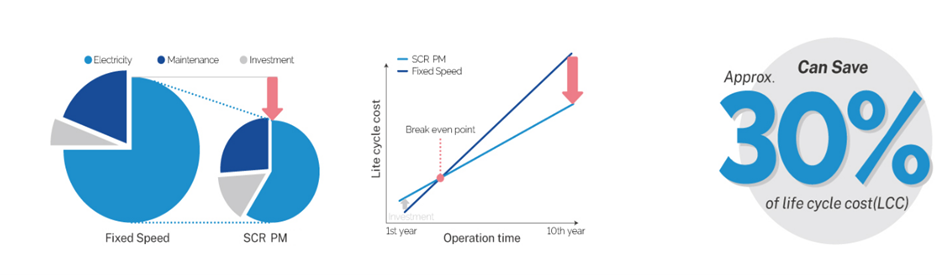

What’s important is not initial cost but life cycle cost. INVERTER compressors may look more expensive than fixed speed model, but many customers choose them because they know importance of life cycle cost & return on investment when it comes to choosing compressors.